Forced Draft Pilots

STACKMATCH Forced Draft Pilots cover many applications and can be retrofitted to meet the customer’s needs. These pilots are equipped with our patented Micro Flame Front Ignition. We manufacture two sizes based on mounting requirements. They come with a retractable flange option which allows users to close the valve on a unit without completely removing the pilot precluding the escape of process gases. The pilot can also be manufactured with a fixed flange if retraction is not required. These pilots can be made to operate on a variety of gases including Natural Gas, Propane, and Hydrogen..

DRAM (Dual Range Air Mixed)

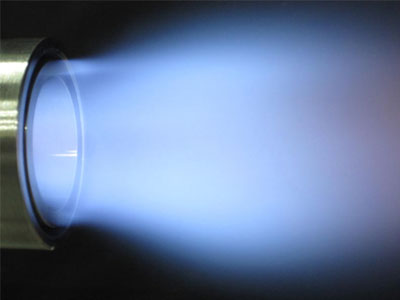

2 Inch DRAM Flame showing separation of secondary and primary flame using “COOL TIP” technology.

DRAM (Dual Range Air Mixed)

2 Inch DRAM Flame. Another view of the flame using natural gas as pilot source.

DRAM (Dual Range Air Mixed)

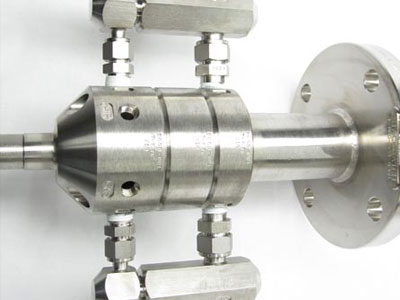

2 Inch DRAM Non Retractable. Top of 2″ DRAM with single entry air and gas inlets and non retractable flange.

DRAM (Dual Range Air Mixed)

2 Inch DRAM Non Retractable. 2″ DRAM connected with non retractable flange.s inlets and non retractable flange.

DRAM (Dual Range Air Mixed)

2 Inch DRAM Nozzle. End of 2″ DRAM showing “COOL TIP” technology.

Forced Draft Pilot Applications

-

Sulfur Recovery Unit (SRU)

-

Tail Gas Units

-

Thermal Oxidizers

-

Incinerators

-

Boilers

-

Claus Units

-

Scot Units

-

Fluid Catalytic Cracking (FCC)

-

Crude Unit Burners

-

Process Heater

-

Process Furnace

-

Air Heaters

-

Any Pressurized Vessel application

DRAM (Dual Range Air Mixed) Pilot

The STACKMATCH DRAM Pilots are the only start-up solution for a Sulfur Recovery Unit ( SRU ), and are used worldwide in Pressurized Vessel and Flare applications such as Tail Gas Treatment Units ( TGTU ), Boilers, Pre-Heaters, Thermal Oxidizers, Crude Unit Burners, etc. Stackmatch Equipment provides efficiency and reliability under the toughest Fired Vessel applications in many industries including Refineries, Chemical, Petrochemical, Natural Gas Processing and Oil & Gas Plants worldwide. The STACKMATCH DRAM is the industry’s only technically advanced and field proven method to start-up your processing unit. It is designed for retrofitting to most existing applications. STACKMATCH advanced technology also provides increased safety while requiring less operator intervention, less down time, lower fuel consumption, maintenance reduction/simplicity and elimination of start-up delays.

Benefits of a DRAM Pilot

-

Micro Flame Front Ignition providing instantaneous positive ignition.

-

Plasma Resonance Flame Detection providing instant and reliable pilot flame verification for unmanned ignition.

-

Cool Tip. Provides extreme longevity in the harshest environments.

-

Instantaneous start-up time. (Both pilot sections are pre-set for variations in vessel pressure)

-

No additional operator adjustments are required

-

Minimal and simple maintenance with less down time

-

Simple installation and operator safety

The STACKMATCH DRAM Pilot is a Forced Draft Gas Fired Pilot and Ignition System designed to be operated in the most extreme atmospheres. With the STACKMATCH Plasma Resonance Flame Detection and reputation for Reliable Ignition with Extreme Flame Stability, the DRAM has proven highly effective as the start-up solution for many Engineers. The DRAM design consists of two parallel and independent Forced Draft Gas Fired Pilots offering flexibility in product application. The pilot is custom sized to fit any main burner requirement and it can be constructed in a fixed or retractable configuration. STACKMATCH has developed several DRAM designs for natural gas and refinery fuel applications, including the 2″ and 1 1/4″ DRAM. Each DRAM can be orifice sized for your application, allowing the DRAM to be used as the primary pilot source and at the same time effectively used as a Pre-Heater to prevent refractory damage during start-up. Ignition and start-up problems on your most difficult applications are solved by using the STACKMATCH DRAM.

DRAM PILOT INTERNAL FUNCTIONS

-

Ignition of Primary Pilot:

Ignition of the DRAM Pilot is instantaneous with properly regulated Air & Gas. The Pilot operation is unaffected by wet or humid conditions. The STACKMATCH Micro Flame Front Ignition method coupled with Low Voltage-High Energy Ignition generates a fireball within the pilot that travels forward to shower the primary nozzle with flame for assured nozzle ignition. Protected internally from external turbulence, this primary pilot flame remains extremely stable.Primary Pilot Flame Detection:

Using our Patented Plasma Resonance Flame Detection technology provides immediate ‘flame on’ or ‘flame off’ detection.Stoichiometric Tracking:

All internal orifices of the DRAM are sized to automatically maintain and track the preset stoichiometric fuel ratios. Preset ratios will not change even during excessive vessel pressure swings and violent turbulence.Secondary Pilot Flame:

Normally, the primary and secondary fuel sources are supplied by a single fuel supply system allowing the primary pilot sensor to sense the entire pilot. If your application requires it, the DRAM can be connected with a separate secondary fuel source allowing primary Pilot operation from a clean dry fuel and secondary Pilot operation using your Refinery Fuel.Electronics:

STACKMATCH Control Systems are designed to operate on voltages based on your power source including AC or DC and can be provided in either explosion proof or non-explosion proof configurations.

DRAM PILOT

Hydrogen DRAM

The STACKMATCH Hydrogen DRAM Pilot is the pilot necessary for gas compositions made primarily of Hydrogen. STACKMATCH has designed this pilot to run on hydrogen and air to start any burner application. With the same principals of the original DRAM, the Hydrogen DRAM runs as effortlessly and efficiently as any other STACKMATCH Pilot.

The Hydrogen DRAM is custom sized to fit any burner requirement and can be constructed in a fixed or retractable configuration. Construction of the pilot is all stainless steel and can hold up to the most inert, corrosive atmospheres. Because of the excessive heat generated by the hydrogen fuel, Plasma Resonance Flame Detection is not offered with the Hydrogen DRAM Pilot. Your existing visual flame detection will suffice. Even though the Hydrogen DRAM lacks flame detection, it still incorporates STACKMATCH’s reliable ignition and extreme flame stability. Our advanced technology also provides increased safety while requiring less operator intervention, less down time, lower fuel consumption, maintenance reduction and elimination of start-up delays.

Benefits of the Hydrogen DRAM

-

Micro Flame Front Ignition providing instantaneous positive ignition

-

Quick start-up time

-

Pilot is pre-set for variations in vessel pressure

-

No additional operator adjustments are required

-

Minimal maintenance

-

Small footprint for easy installation

-

Safer for System operator

Mechanical Features

-

-

Flange sized to customer specification

-

Requires a 2″ diameter or larger opening

-

Constructed to customer applications length

-

Operates from 88% to 100% Hydrogen fuel source

-

Gas and Air inlets are 1/2″ NPT

-

Normal gas and air pressure is set at 30 PSI unless specified otherwise

-

Electrical options are 110 or 220 @ 50-60 Hz

-

Uses less than 1 amp for continuous service

-